EMC believes that the implementation of corporate sustainability management cannot be limited to the company itself. The potential indirect environmental and social impacts caused by the supply chain must also be properly managed.

|

Material Topic |

Sustainable Products (including product development and the introduction of environmentally friendly materials into production), and product safety and quality |

|

|

Policy Commitment |

By adhering to the concept of environmentally friendly management, EMC strives to develop environmentally friendly materials to meet the future needs of the global market. |

|

|

Sustainability Indicator |

2024 Targets and Performance |

Short-term, Medium-term, and Long-term Goals |

|

Ratio of halogen-free/green materials |

In 2024, EMC’s sales were concentrated in Taiwan and the People’s Republic of China. The primary export market was South Korea. The Company aims to increase the sales of high-end products (Hi-Tg. Br-Free, Low CTE, etc.) to a percentage higher than 60%. Among the numerous CCL manufacturers in Taiwan, EMC has gained a position in the global market as a leading manufacturer of halogen-free CCL, with a market share as high as 33%. As indicated in the data released by Prismark in 2024, EMC’s global share was approximately 10%. |

Continue to increase the market share so that by 2035, the Prismark Report will reveal that EMC’s share of the halogen free/green materials market has reached 40%, securing its leading position. |

|

Development of low-carbon raw materials |

A low-carbon formula was adopted, replacing petroleum epoxy resins with resins composed of 25% of bio-based content, which will reduce carbon dioxide emissions by 20 tons per year. |

Gradually increase the ratio of bio-based/ environmentally friendly raw materials used in EMC’s product manufacturing to 50% by 2035. |

|

Material Topic |

Supply Chain Management |

|

|

Policy Commitment |

1. EMC requires its major raw material suppliers (except traders/agents) to sign a Social Responsibility Commitment, which requires suppliers to comply with the Labor Act and social ethics and reinforces the suppliers’implementation of social responsibilities. EMC also requires suppliers to sign the Declaration of Conflict-free Metals, ensuring that the supplied products contain no conflict metals. 2. Implement the supply chain assessment/evaluation and auditing system for supply chain management to minimize the risk of supply chain failure. |

|

|

Sustainability Indicator |

2024 Targets and Performance |

Short-term, Medium-term, and Long-term Goals |

|

Where copper foil is the main material used, the percentage locally procured |

Taiwan plants ≧ 93% Elite Electronic Material (Kunshan) ≧ 43% Elite Electronic Material (Zhongshan) ≧ 36% Elite Electronic Material (Huangshi) ≧ 56% |

Taiwan plants ≧ 100% Elite Electronic Material (Kunshan) ≧ 50% Elite Electronic Material (Zhongshan) ≧ 50% Elite Electronic Material (Huangshi) ≧ 60% |

|

Percentage of recycled copper contained in copper foil |

Taiwan plants: 100% Elite Electronic Material (Kunshan): 100% Elite Electronic Material (Zhongshan): 100% Elite Electronic Material (Huangshi): 100% |

Taiwan plants: Reach 100% Elite Electronic Material (Kunshan): Reach 100% Elite Electronic Material (Zhongshan): Reach 100% Elite Electronic Material (Huangshi): Reach 100% |

|

All new suppliers are assessed in accordance with the New Supplier Assessment Procedures, which cover environmental management and corporate social responsibility requirements |

EMC’s four major production bases onboarded 16 new suppliers in 2024. 100% of new suppliers were assessed in accordance with the New Supplier Assessment Procedures, which cover environmental management and corporate social responsibility requirements. |

100% of new suppliers are assessed in accordance with the New Supplier Assessment Procedures, which cover environmental management and corporate social responsibility requirements. |

Green and Low-carbon Product Design

n Product and Quality Management

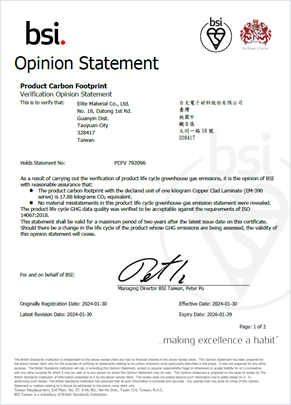

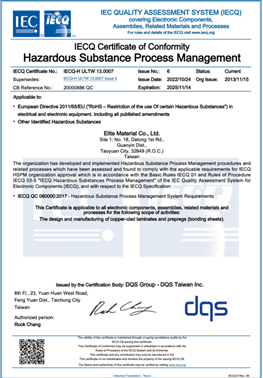

As a leading manufacturer in the global CCL market, EMC consistently strives to achieve excellent product quality, treating this as one of its corporate visions. By strictly adhering to international quality management standards, EMC has obtained the ISO 9001, IATF 16949, AS 9100, and QC 080000 certifications in recognition of its quality management systems. Internal monitoring and improvement mechanisms have also been implemented to continuously improve the quality management systems.

EMC’s Quality/Hazardous Substance Compliance Management and Control Policy is based on the principles of hazardous substance management and continuous pursuit of quality improvement. Throughout the complete production process―from raw material selection, product design, and manufacturing to final delivery―all EMC products undergo quality testing and hazardous substance compliance testing to ensure compliance with quality and hazardous substance regulations.

EMC has established a Hazardous Substances Management Committee to proactively promote the use of eco-friendly materials that reduce environmental impacts. The committee is chaired by the head of the Manufacturing Department, who is responsible for convening committee members to review and confirm customers’ hazardous substance requirements and assess the feasibility of such requirements. Moreover, the committee also formulates relevant hazardous substance control standards to promote management requirements and hazardous substance compliance policies for all subordinate units. The goal of “zero hazardous-substance-related complaints” was achieved in 2024.

|

|

|

|

|

ISO 9001:2015 Certificate |

IATF 16949:2015 Certificate |

AS 9100 Certificate |

QC 080000 Certificate |

Moreover, EMC always pays attention to customer needs and feedback. The Company is committed to continuously introducing innovation and improvements into its product designs and manufacturing processes, as well as applying advanced technologies and innovative methods in product design and development to ensure the top-level function and performance of its products compared with other products in the industry. EMC aims to enhance customer satisfaction and promote sustainable development through high quality and advanced products. EMC strictly follows relevant quality control and management procedures throughout all stages of product development to ensure the regulatory compliance of every design and development process. Based on the unwavering principles of sustainable management and hazardous substance compliance management, EMC prioritizes the use of eco-friendly materials during product development and strives to protect the environment while improving product quality.

n Life Cycle-Based Low-Carbon Product Design

In light of the increasingly severe environmental impacts of global warming and climate change, EMC cares about how its products affect the environment throughout the product life cycle. Therefore, the Company initiated a product carbon footprint survey for the

EM-390 series CCL products in 2022, confirming that more than 60% of the carbon emissions are generated during the design stage (i.e., the raw material stage).

|

Life Cycle Stage |

Carbon Emissions per Kilogram (Kg CO2e) |

Percentage |

|

Raw Material Acquisition Stage |

11.263 |

63.01% |

|

Manufacturing Stage |

6.613 |

36.99% |

|

Total |

17.876 |

100% |

|

|

|

Hazardous Substance Management

EMC’s Hazardous Substance Management Procedure covers the European Union’s Restriction of Hazardous Substances Directive (EU RoHS), the EU’s chemicals policy (Registration, Evaluation, Authorization, and Restriction of Chemicals – REACH), IEC 61249-2-21 halogen-free regulations, and other international environmental protection regulations and industry standards. To ensure that product quality aligns with green-product related environmental protection regulations, EMC has formulated incoming inspection procedures for materials and set up fluorescent X-ray hazardous substance analyzers for non-destructive measurement of hazardous substance content in raw materials, packaging materials, semi-finished products, and finished products. Suppliers are also required to ban the use of hazardous substances in their production and products, and they are required to sign an Environmental Assurance Agreement (Declaration of Non-use) to ensure that the products meet the requirements of RoHS, REACH, and other relevant environmental regulations. The trend of green environmental protection continues to gain momentum, leading to greater demand for HDI boards, layer boards, IC substrates, and rigid-flex boards that can be applied to portable products such as mobile phones and consumer electronics to make them environmentally friendly. As a result, high-performance environmentally friendly CCL has enormous growth potential, and this will be the focus of future development for PCB products.

Furthermore, every year, a third-party notarization unit is commissioned to carry out regular material testing on raw materials, packaging materials, semi-finished products, and finished products of EMC plants. This ensures that EMC’s products are 100% in compliance with the requirements of RoHS, REACH, and other laws and regulations.

Halogen-free Regulations

In response to the rising awareness of environmental protection worldwide and the increasingly competitive industrial environment after the implementation of RoHS regulations by the European Union, EMC has worked hard over the years to meet the requirements and has become the world’s largest supplier of halogen-free eco-friendly materials for HDI PCBs. The Company has taken the initiative to expand the development of halogen-free eco-friendly materials for 5G, Netcom infrastructure, and automotive related applications. EMC continues to explore new market frontiers by seeking niche products for each plant, increasing the added value of existing products, and innovating new high-added-value products. Additionally, to provide customers with the latest product information, product development results are displayed on the company’s website.

New Types of Green Products with High Performance and Low Pollution

EMC continues the development of glass-fiber-cloth-free build-up film products. In addition to adhesive-coated CCL, build-up film is another key product that the Company has adopted to gradually reduce its use of glass-fiber cloth. To uphold the corporate policy of using halogen-free eco-friendly materials, EMC is introducing new manufacturing processes and methods to reduce the use of solvents and the waste glue generated by production processes, which will significantly reduce the amount of waste generated. As for the targets for glass-fiber cloth use reduction, based on demand forecasts, the monthly demand for glass-fiber cloth in 2025 will be 500,000–900,000 m2, and the annual demand will be approximately 6,000,000–11,000,000 m2. Accordingly, the use of glass-fiber cloth can be reduced by approximately 6,000,000–11,000,000 m2 per year. For example, the thickness of the insulation layer in a server motherboard ranges from 50 um to 510 um, of which glass-fiber cloth accounts for 23–47% of the thickness. The same thickness can be achieved with adhesive-coated CCL and build-up film, which eliminates the need for glass-fiber cloth and is expected to effectively reduce carbon emissions and energy consumption.

Development of Low-carbon Raw Materials

Among the carbon footprint reduction approaches proposed by the CCL industry, in addition to energy saving and the use of renewable energy, product carbon footprint reduction through green product formula design is another future trend for CCL product development. Since polymer resins and functional fillers are key materials in CCL product formulas, adopting low-carbon resins and recycled fillers is an effective strategy to reduce the carbon footprint of products. In terms of low-carbon resins, EMC adopts several bio-based epoxy resins as sustainable alternatives to petroleum-based epoxy resins in its low carbon product formula design. By gradually introducing bio-based epoxy resins in low-carbon formulas, the Company can reduce its carbon emissions by 50 tons of CO2 emissions per year. Additionally, EMC labs have introduced recycled fillers and performed relevant formula verification. The verification testing results validated that the formulas yielded products meeting specification requirements, showing that the carbon footprint of products can be further reduced in the future.

Percentage of recycled copper contained in copper foil

The overwhelming development of the global economy has resulted in the rapid consumption of the Earth’s limited resources. Sustainable utilization and development of resources has become an international consensus, and “circular economy” has become an important issue for social and economic development. Copper foil is one of EMC’s important raw materials, and all of the Company’s suppliers can provide products containing 100% recycled copper. This will facilitate resource efficiency and contribute to building a circular economy-based society. (Percentages of suppliers weighted based on shipment amounts.)

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

|||||

|

Year |

2023 |

2024 |

2023 |

2024 |

2023 |

2024 |

2023 |

2024 |

|

Percentage of recycled copper contained in copper foil (Weighted total percentage) |

100% |

100% |

87% |

100% |

97% |

100% |

90% |

100% |

Sustainable Supply Chain Management

n Supply Chain Management Policy

EMC believes that the implementation of corporate sustainability management should not be limited to the Company itself―the potential indirect environmental and social impacts caused by the supply chain must also be properly managed. In order to communicate EMC’s supply chain management requirements and ensure that the Company’s core values extend throughout the supply chain, EMC has long established a complete supplier management system. In addition to upholding strict quality requirements, the Company expects all suppliers to practice corporate social responsibility through abiding by general social ethics, the principle of good faith, and environmental protection regulations for products and operations. During daily procurement operations, in addition to considering the criteria of cost and quality, the Company also evaluates and audits suppliers’ performance of labor rights protection, environmental protection, and safety and health management. Moreover, improvement measures are developed based on assessment results to assist suppliers in making continuous progress, thereby enhancing supply chain sustainability management quality, reducing supply chain operational risks, and establishing sustainable and supportive partnerships. The demand for high-end materials continued to increase in 2024. With proper supply planning and scheduling, along with suppliers’ collaborative efforts, customer needs were fully met.

n Implement Local Procurement Principles

Copper Clad Laminate (CCL) is a key basic material for PCB production. It is made by combining several components, including a resin, a hardener, a promoter, and a reinforcing material (e.g., glass-fiber cloth). The process involves impregnating the reinforcement with a resin mixture to create a pre-impregnated material (prepreg). The prepreg is then checked and cut into the desired shape and size. Several layers of prepreg are then stacked and covered with copper foil. This stack undergoes thermocompression to bond the layers together, followed by trimming, inspection, and final cutting to produce the CCL. Among the numerous CCL manufacturers in Taiwan, EMC has gained a position in the global market as a leading manufacturer of halogen-free CCL, with a market share as high as 33%. In 2024, EMC’s sales were concentrated in Taiwan and the People’s Republic of China. The primary export market was South Korea. EMC aims to increase the sales of high-end products (Hi-Tg. Br-Free, Low CTE, etc.) to a percentage higher than 60%. As indicated in the data released by Prismark in 2024, EMC’s global share was about 10%

EMC’s main product, CCL, is a midstream product of the PCB industry chain. The downstream consists of suppliers of various electronic products. The entire PCB industry chain is illustrated as follows:

|

Upstream |

Midstream |

Downstream |

|

Glass fiber/glass cloth Epoxy resin Phenolic resin Copper foil Polyimide resin Production process and testing equipment |

CCL Manufacturing of RPCB, FPCB, and IC Substrate Substrate assembly/processing and related manufacturing |

Varius electronic products |

|

2024 Purchase percentage from local suppliers (calculated based on payment amount) |

||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

|

|

Copper foil |

93% |

43% |

36% |

56% |

|

Glass-fiber cloth |

83% |

51% |

39% |

90% |

|

Chemicals |

21% |

60% |

61% |

51% |

During the 2024 reporting period, EMC maintained the same operating model as the previous year in terms of its industry positioning, product and service categories, supply chain structure, and major sales markets. No significant changes were identified in the listed aspects. The organization’s upstream and downstream value chain structure, as well as its major business relationships, did not undergo any significant adjustments or structural changes.

n Supplier Management Procedures

To ensure that the raw materials provided by EMC’s suppliers meet the Company’s quality requirements and customer requirements while adhering to RoHS, Hazardous Substances Free (HSF), and relevant laws and regulations, thereby enhancing the Company’s productivity and competitiveness, EMC has formulated the Supplier Management Procedures.

EMC has formulated its Supplier Management Procedures based on the rules and regulations set by the Responsible Business Alliance (RBA) and related international organizations as well as the Company’s existing supplier evaluation and audit criteria. Through a process of review, evaluation, and audit, EMC controls the risks associated with its major raw material suppliers and ensures sustainable management. By reviewing, evaluating, and auditing suppliers’ environmental, labor, human rights, and social performance, the Company can select suitable suppliers while fulfilling its management responsibility.

|

Workflow |

Responsible Unit |

Relevant Explanation |

Output (Form/Record/Document) |

|||

|

|

Supplier Assessment Group |

CCL Supplier Management Procedures |

New Supplier Development and Risk Assessment Form |

|||

|

|

|

|||||

|

|

|

|

||||

|

|

CCL Supplier Management Procedures Operating Regulations for Supplier Quality Assessment |

Supplier Audit and Assessment Report |

||||

|

Supplier Assessment Group |

|

Audit-identified Deficiency Review Form Supplier Quality System Status Survey Form Manufacturer Profile Survey Form Agent/Trader Profile Survey Form Social Responsibility Commitment New Supplier Survey Countersigning Sheet Environmental Guarantee(“Non-use” Supporting Documents) List of Eligible Suppliers |

||||

|

|

CCL Supplier Management Procedures |

|||||

|

|

|

|||||

|

|

Operating Procedures for CCL Material Approval |

|||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

||||||

1. New Supplier Assessment

(1)Supplier Assessment and Audit Team: The Team is composed of members from various units, and the auditors’ qualifications must be certified. The supplier assessment must be completed before the formal order is placed.

(2)Content of supplier assessment:

①When assessing a new supplier, the Procurement Department should include six major items for review (see chart below). The new supplier approval procedure will be completed after the assessment results have been countersigned by related units. After approval, the new supplier can be added to the list of eligible suppliers. The assessment is used to better understand the supplier’s operating conditions, financial stability, operational continuity planning, etc., thereby reducing procurement risks

|

No. |

Assessment Item |

|

1 |

New Supplier Development and Risk Assessment Form |

|

2 |

Supplier Quality System Status Survey Form |

|

3 |

Manufacturer Profile Survey Form |

|

4 |

Agent/Trader Profile Survey Form |

|

5 |

Social Responsibility Commitment, Declaration of Conflict Metals |

|

6 |

Supplier Audit and Assessment Report |

②Among the assessment items, Item 6, Supplier Audit and Assessment Report, covers 11 major audit items, including quality system, resource management, design and development, procurement, production control, monitoring and measurement, continuous improvement of performance, operation and management, corporate social responsibility, hazardous substance management, and environmental safety and health management system.

③Assessment rating

In 2024, a total of 16 new suppliers were added to the supplier lists of EMC’s four major production plants. 100% of the new suppliers were assessed based on the requirements specified in the New Supplier Assessment Procedures, which cover environmental management and corporate social responsibility.

|

Rating |

Description |

2024 New Supplier Assessment Results |

|||||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||||

|

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

||

|

Qualified Score: 80–100% |

Collaboration with the supplier is allowed. |

9 |

90% |

2 |

100% |

2 |

100% |

2 |

100% |

|

Conditionally approved Score: 70–79% |

Collaboration with the supplier is allowed; however, the supplier is required to make improvements. Re-audit will be carried out within 6 months; if the score is still below 80%, further collaboration with the supplier is not allowed. |

1 |

10% |

0 |

0 |

0 |

0 |

0 |

0 |

|

Failed The score is below 70% or the score of an individual item is below 70% |

Collaboration with the supplier is not allowed. |

0 |

0% |

0 |

0 |

0 |

0 |

0 |

0 |

④Additionally, EMC requires its major raw material suppliers (except traders/agents) to sign the Social Responsibility Commitment, which requires them to comply with the Labor Act and social ethics, and reinforces their implementation of social responsibilities. EMC also requires its suppliers to sign the Declaration of Conflict-free Metals to ensure that supplied products contain no conflict metals.

|

Number of suppliers signing the Social Responsibility Commitment, and the achievement rate in 2024 |

|||||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||

|

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

|

68 |

100% |

44 |

100% |

50 |

100% |

45 |

100% |

⑤EMC requires all of its major raw material suppliers to sign and return the Declaration of Conflict-free Metals, stating and guaranteeing that they have not obtained gold, tantalum, tungsten, cobalt, tin, or palladium through non-government militant groups, illegal groups, mining areas in the conflict zone of the Democratic Republic of the Congo, or illegal smuggling. Metals exported from the following countries (“conflict areas”) do not comply with the Conflict-free Specifications: Democratic Republic of the Congo, Rwanda, Uganda, Burundi, Tanzania, and Kenya. EMC will conduct supplier evaluations and audits to track suppliers’ performance until relevant critical issues are improved, and provide continuous education and training for suppliers to progress.

|

Number of suppliers signing the Declaration of Conflict-free Metals, and the achievement rate in 2024 |

|||||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||

|

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

|

68 |

100% |

101 |

100% |

110 |

100% |

89 |

100% |

⑥Signing of Integrity Statement (new requirement added in 2024)

In 2024, as required by the RBA Code of Conduct, suppliers were required to sign an Integrity Statement preventing them from engaging in activities that could result in improper gains or harm the Company or its investors.

|

Number of raw materials suppliers signing the "Integrity Statement" and the achievement rate in 2024 |

|||||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||

|

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

No. of suppliers |

Percentage |

|

53 |

78% |

92 |

91% |

101 |

92% |

81 |

91% |

2. Qualified Supplier Evaluation (current suppliers)

EMC regularly evaluates qualified suppliers. The evaluation items include:

① Monthly evaluation items:

|

Responsible unit |

Evaluation items |

|

Quality Assurance Department |

Evaluates incoming material quality, process quality, customer quality, VCAR response, abnormal recurrence, and data provision, and summarizes the scores with ratings. |

|

Procurement Department |

Evaluates price satisfaction, delivery control, service, degree of cooperation, and future trajectory, and summarizes the scores with ratings. |

② Annual evaluation items

The Supplier Audit and Assessment Report covers 11 major items. In 2024, none of the suppliers who completed the audit procedures was deemed ineligible due to unsatisfactory performance of corporate social responsibility or EHS management system practices.

3. Evaluation rating

|

Rating |

Description |

2024 Evaluation Results |

||||

|

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

|||

|

Grade A |

Excellent: 90.01 or higher |

Expand the area and scope for collaboration |

600times |

837times |

853times |

667times |

|

Grade B |

Good: 75.01–90.00 |

Maintain normal procurement volume |

93times |

104times |

93times |

142times |

|

Grade C |

Remediation: 60.01–75.00 |

Reduce procurement volume without affecting customers’ demand and the plant’s normal supply |

7times |

2times |

1times |

1times |

|

Grade D |

Limited: 00.00–60.00 |

Remove the supplier’s eligibility if improvements are not made within a specified time limit |

0times |

0times |

0times |

0times |

Note: If a supplier has been rated as Grade C for 2 consecutive months, the procurement volume will be reduced, and the supplier will be asked to come to the plant for performance review and improvement.

EMC’s Quality Assurance Department and Procurement Department should conduct supplier evaluations on a monthly basis. For a Grade A supplier with a score of 90.01 or higher, the area and scope of collaboration will be expanded and the procurement volume increased. For a Grade B supplier with a score falling in the range of 75.01–90.00, the normal procurement volume will be maintained. For a Grade C supplier with a score falling in the range of 60.01–75.00, remedial assistance will be provided (the procurement volume will be reduced, without affecting customers’ demand and the plant’s normal supply, and if a supplier is rated as Grade C for 2 consecutive months, they will be asked to join a review meeting and receive the Company’s guidance for improvement; if a supplier if rated as Grade C for 3 consecutive months, they will be downgraded to Grade D.) For a Grade D supplier with a score falling in the range of 00.00–60.00, the supplier will be asked to make improvements within specified time limit; if the supplier’s next score is still under 60, they will lose their qualified status.

Additionally, the Evaluation Group should evaluate major qualified suppliers on a yearly basis. The Evaluation Group is composed of members from units such as quality assurance, production, technology, material development, procurement, etc. Personnel from other units may also be included as needed. If a supplier’s total score or their score for any individual item is below 70%, then collaboration with that supplier will be suspended.

|

Annual Assessment/Evaluation Result |

Guanyin Plants and Hsinchu Plant |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

Total |

|

Qualified |

15 |

14 |

16 |

4 |

49 |

|

Unqualified |

0 |

0 |

0 |

0 |

0 |

Customer Relationship Management

Customer Satisfaction:

By adhering to a people-focused philosophy, EMC strives to provide customers with the best quality through reliable products and comprehensive services. The Company is also committed to maintaining the overall social benefits and ecological value of its products and services through applications that facilitate the development of society and civilization as well as mankind’s environment and survival, and it will take further steps to achieve the ultimate goal of customer satisfaction.

The Company conducts a biannual

questionnaire survey to analyze market needs from customers’ points of view,

and it strives to comprehensively respect and

safeguard customers’ interests by precisely grasping market trends and

situations, thereby exceeding customers’

expectations. It goes without saying that sales personnel act as a

communication channel between customers and the Company.

However, providing good customer service and improving customer satisfaction is

not the responsibility of the Business Department

alone; all employees contribute to this goal through their continuous efforts.

EMC attaches great importance to customers’

rights, interests, and opinions, and has maintained continuous positive

interaction and communication with customers, forming

a virtuous circle for mutual growth and creating a win–win partnership.

Satisfaction Survey Results:

The return rate of the Customer Satisfaction Questionnaire sent in the first half of 2024 was 100%, and the average customer satisfaction rate was 70.6%. The survey results showed that customers were satisfied with EMC’s performance in terms of quality, price, reliability, and after-sales service. EMC continued to make progress during the second half of the year; the return rate of the Customer Satisfaction Questionnaire sent in the second half of 2024 was 100% (11 questionnaires were sent to major customers), and the overall customer satisfaction rate was 74.5%―an increase of 3.9% compared to the first half of the year. The survey results showed that customers were satisfied with EMC’s performance in terms of delivery, quality, price, reliability, and after-sales service.

Company L awarded the highest score (83). Most of the companies’ scores increased slightly. Confronted with the challenge of high demand for AI-related items during the second half of the year, EMC continued to improve in all aspects and sustained a high level of customer satisfaction. EMC’s products are in high demand on the market. The Company has maintained its role as a leading manufacturer in green/eco-friendly materials for consumer electronics and become the world’s second largest manufacturer of green materials for servers and switches―and it continues to grow. By holding fast to a customer-centric philosophy and continuously receiving feedback and opinions from customers, EMC continues its improvement and progress to exceed customer expectations for excellence and innovation.

|

2024 First-Half Year, Customer Satisfaction Survey Report |

||||||||||||

|

Customer ID & Abbreviation |

Price |

Design |

Quality |

HSF (Data feedback) |

Delivery |

Reliability |

Response |

Service |

Cooperation |

HSF (Management) |

Sub TTL |

|

|

1 |

W |

0 |

10 |

8 |

8 |

2 |

8 |

8 |

8 |

8 |

10 |

70 |

|

2 |

U1 |

2 |

10 |

10 |

10 |

2 |

10 |

5 |

10 |

2 |

10 |

71 |

|

3 |

U2 |

5 |

10 |

8 |

5 |

5 |

5 |

5 |

5 |

8 |

10 |

66 |

|

4 |

G |

5 |

2 |

2 |

8 |

5 |

8 |

8 |

8 |

10 |

10 |

66 |

|

5 |

C |

5 |

8 |

8 |

8 |

5 |

8 |

8 |

8 |

8 |

10 |

76 |

|

6 |

F |

4 |

6 |

7 |

8 |

4 |

7 |

6 |

7 |

7 |

10 |

66 |

|

7 |

A |

5 |

8 |

8 |

8 |

5 |

8 |

8 |

8 |

8 |

10 |

76 |

|

8 |

I |

8 |

8 |

5 |

8 |

5 |

8 |

5 |

8 |

8 |

10 |

73 |

|

9 |

M |

5 |

5 |

5 |

5 |

8 |

8 |

8 |

8 |

5 |

10 |

67 |

|

10 |

L |

5 |

7 |

7 |

9 |

8 |

5 |

8 |

8 |

8 |

10 |

75 |

|

Sub TTL |

44 |

74 |

68 |

77 |

49 |

75 |

69 |

78 |

72 |

100 |

706 |

|

|

Avg. |

4.4 |

7.4 |

6.8 |

7.7 |

4.9 |

7.5 |

6.9 |

7.8 |

7.2 |

10.0 |

70.6 |

|

|

2024 Second-Half Year, Customer Satisfaction Survey Repor |

||||||||||||

|

Customer ID & Abbreviation |

Price |

Design |

Quality |

HSF (Data feedback) |

Delivery |

Reliability |

Response |

Service |

Cooperation |

HSF (Management) |

Sub TTL |

|

|

1 |

W |

2 |

8 |

8 |

8 |

2 |

8 |

8 |

8 |

8 |

10 |

70 |

|

2 |

U1 |

2 |

10 |

10 |

10 |

5 |

10 |

2 |

10 |

5 |

10 |

74 |

|

3 |

U2 |

5 |

10 |

5 |

5 |

5 |

8 |

8 |

8 |

8 |

10 |

72 |

|

4 |

G |

5 |

8 |

6 |

5 |

5 |

8 |

6 |

8 |

6 |

10 |

67 |

|

5 |

C |

2 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

10 |

76 |

|

6 |

F |

5 |

7 |

8 |

8 |

6 |

8 |

7 |

7 |

8 |

10 |

74 |

|

7 |

A |

5 |

8 |

8 |

8 |

5 |

8 |

8 |

8 |

8 |

10 |

76 |

|

8 |

I |

8 |

8 |

5 |

8 |

2 |

8 |

8 |

8 |

8 |

10 |

73 |

|

9 |

M |

5 |

10 |

8 |

10 |

5 |

8 |

5 |

10 |

10 |

10 |

81 |

|

10 |

L |

5 |

8 |

10 |

10 |

8 |

8 |

8 |

8 |

8 |

10 |

83 |

|

11 |

S |

5 |

8 |

8 |

8 |

5 |

8 |

8 |

8 |

5 |

10 |

73 |

|

Sub TTL |

49.0 |

49 |

93 |

84 |

88 |

56 |

90 |

76 |

91 |

82 |

110 |

|

|

Avg. |

4.5 |

4.5 |

8.5 |

7.6 |

8 |

5.1 |

8.2 |

6.9 |

8.3 |

7.5 |

10 |

|