Building a Safe and Healthy Workplace

EMC attaches great importance to the safety and health of its employees. The primary focus is to establish a healthy, safe and comfortable work environment through precautionary measures such as change management, risk assessment, risk mitigation, and risk elimination to improve the work environment and minimize the incidence of work-related diseases. Additionally, to achieve sustainable development based on safety, health, and environmental protection, appropriate assessment tools have been adopted to formulate management plans for day-to-day operations. Only by adhering to safety, health, and environmental protection while pursuing corporate development can the goal of sustainable operations be achieved.

|

Material Topic |

Occupational Safety and Health Management |

|

|

Policy commitment |

1. Committed to building a safe workplace in accordance with various standard procedures required by the ISO 45001:2018 Occupational Safety Management System to enable every employee to work under safe conditions. 2. Standard operating procedures for workplace safety and employee health management should be established by on-site units at all factories. In addition to regular education and training on safety and health, simulation exercises aiming at reinforcing the concepts from the education and training and promotion of management related to work environments, equipment, and hazardous substances should be held to ensure the safety and health of employees. |

|

|

Sustainability Indicator |

2024 Evaluation Mechanism and Performance |

Medium- and Long-term Goals |

|

Promoting safety culture |

Occupational safety and health education and training: 100% completion rate for employees; 100% completion rate for contractors |

|

|

Providing a safe work environment |

Employees’ Disabling Injury Frequency Rate (FR) < 3 |

Employees’ Disabling Injury Frequency Rate (FR)<2 |

|

Employees’ Disabling Injury Severity Rate (SR) < 144 |

Employees’ Disabling Injury Severity Rate (SR)<30 |

|

|

Safeguarding employee health |

Compliance with regulatory health check items |

Add two more items to surpass the regulatory health check system (Taiwan region) |

Occupational Safety and Health Management

n Occupational Health and Safety Management System

|

EMC’s EHS Policy Legal Compliance, Risk Control Pollution Prevention, Conservation, and Waste Reduction Consultation, Communication, and Continuous Improvement |

With the aim of accomplishing the EHS policy, the company makes the following commitments: 1. Comply with EHS laws and regulations, protect workers’ safety and health, and control the risks of potential environmental pollution and safety accidents. 2. Implement system management to prevent pollution and reduce energy and resource consumption, thereby achieving energy and resource conservation. 3. Take appropriate management measures to control the risks of hazards such as confined spaces, falls, chemical hazards, fire and explosion, mechanical equipment injuries, electric shocks, etc. 4. Provide opportunities for consultation and communication through various meetings so that all employees and collaborative companies are aware of and understand the company’s EHS Policy and its meaning, and set goals for continuous improvement. |

EMC strives to create a safe and healthy workplace so that every employee can work comfortably and return home safely. However, a safe work environment cannot be achieved merely through the upgrade of relevant soft and hard safety facilities― it requires the cooperation of every employee. The Safety and Health Department and on-site units have established standard operating procedures for workplace safety and employee health management. In terms of managerial training on work environments, equipment, and hazardous substances, regular education and training as well as simulation exercises are held to ensure the safety and health of employees. To ensure the normal operation of machinery and equipment, the company strengthens equipment operation management, personnel training, and inspection/maintenance routines and also improves the dust collection system. The implemented based on the goals set to address potential impacts identified by each department during annual hazard identification. The Occupational Safety and Health Committee is responsible for tracking quarterly progress and examining the effectiveness of implementation in accordance with the Improvement Tracking Form to ensure the realization of the EHS policy.

EMC emphasizes occupational safety and health management performance and is committed to providing efficient operating services with a low environmental burden that prioritize the safety and comfort of stakeholders such as employees, customers, communities, and related operating partners. By upholding the principles of “improving the safety and health of work environments, protecting employees, and reducing occupational injuries”, EMC enhances its overall infrastructure to gradually improve employees’ work environments and enable employees to devote themselves to their work. The Company has set up Occupational Safety and Health Management Systems based on the management requirements formalized in international standards and related laws and the regulations announced by the Ministry of Labor in Taiwan, and successfully migrated to (ISO 45001:2018). In accordance with the requirements of standardized operating procedures, the Company demands that every element of the production process must strictly abide by the safety principles, employees’ safety awareness must be reinforced, and workplace safety should never be overlooked. The causes of occupational accidents must be clarified and thoroughly analyzed so as to develop follow-up prevention strategies and handling procedures.

EMC has introduced the Occupational Safety and Health Management Systems (ISO 45001) at its Headquarters and all production plants and has been verified by a third-party independent verification organization. Additionally, EMC has set up occupational safety and health management units and dedicated personnel to take the responsibility for drafting, planning, supervising, and promoting safety and health management items and guiding relevant units to implement corrective and preventive measures for disasters/accidents in hope that workplace hazards can be reduced and safety and health management levels enhanced. The scope of the Company's management systems covers all workers who perform work activities under the control of the Company’s Taiwan plants and Mainland China plants, including employees (accounting for 96.4%) and non-employees (accounting for 3.6%).

|

|

|

|

|

|

EMC’s Taiwan Plants |

Elite Electronic Material (Kunshan) Co., Ltd. |

Elite Electronic Material (Zhongshan) Co., Ltd. |

Elite Electronic Material (Huangshi) Co., Ltd. |

n Hazard identification, Risk Assessment and Incident Investigation

Hazard Identification and Risk Assessment Procedures

EMC emphasizes workplace safety and health based on the principles of Advance Preparation, Zero Accidents, and Zero Disasters. The scope of these principles encompasses the company’s routine operations and other people engaged in activities at EMC’s work sites (including contractors, visitors, and suppliers). The Occupational Safety and Health Management System Promotion Team reviews the results of hazard identification and risk assessment in accordance with the Hazard Identification and Risk Assessment Management Procedures on a yearly basis (by referencing the Procedures for Hazard Identification and Risk Assessment), and then takes corresponding improvement and control/management measures based on the risk levels. The risk levels (five levels in total) are determined based on the frequency of hazards, the likelihood of injuries, and the severity of injuries (with reference to the Judgment Criteria for Hazard Identification and Risk Assessment). For unacceptable risks (level 1 to level 3), measures such as elimination, substitution, engineering controls, education and training, and personal protective equipment must be taken, and improvement effectiveness must be continuously tracked. Moreover, workers are allowed to leave work conditions and places that they think may cause injury or ill health without being targeted by punitive measures such as pay deduction, salary cut, or leave deprivation.

Procedures for Hazard Identification and Risk Assessment

|

|

1. Targets for hazard identification and risk assessment Personnel who are engaged in work or work-related activities supervised by the organization. Such personnel may be worker employe by the organization or other personnel, including senior managers, managerial personnel, non-managerial personnel, personnel from external manpower dispatch companies, contractor workers, individuals, or other personnel whose work or work-related activities are jointly supervised by the organization. 2. Scope of hazard identification and risk assessment (1) Identify potential hazard factors existing in the workplace’s basic facilities, machinery and equipment, materials, substances, operating environment, manufacturing processes, operating procedures, operational activities, products, services, etc., and then assess the possible risks, determine unacceptable risk levels, and take measures to address the unacceptable risks, such as elimination, substitution, engineering controls, education and training, or personal protective equipment. (2) The identification and assessment of contracted operators’ risks along with the control methods are discussed during pr construction safety meetings and consultative organization meetings. (3) In the event of changes to processes, raw materials, or operating environment conditions or the addition of new equipment, personnel shall follow the Procedures for Change Management Operation and conduct pre-change safety assessments to increase safety and protective measures, assess the use of low-hazard chemicals to substitute for high-hazard chemicals, etc. to ensure the safety and health of the organization’s personnel. |

Incident Investigation

An occupational accident reporting system has been established based on the ISO 45001 Occupational Safety and Health Management Systems, and dedicated units have been designated to manage occupational safety and health performance and relevant occupational accident metrics. According to the occupational accident statistics over the years, the occupational accident type with the highest incidence is traffic accidents, followed by incidents of being caught/ drawn in by machinery and incidents of being crushed/smashed.

The total number of accidents in 2024 decreased by one case compared to 2023. An exceptional accident happened in May 2024. Two Hsinchu Plant workers were moving through a ceiling cavity toward the plant’s rear section to perform a maintenance check of air conditioning equipment vents to identify condensation issues. The workers did not report to their supervisor nor did they apply for approval for elevated operations for the maintenance check. The workers were not wearing safety gear, and they sustained injuries after accidentally stepping on a light steel joist ceiling structure and falling from height. To resolve this issue, the light steel joist ceilings in plant areas have been converted to Ku-ban panel ceilings. Keys are used to control ceiling access, and personnel are required to register operator and safety layout information with supervisors before operations are carried out. Moreover, operators must request approval for elevated operations from EHS personnel before carrying out maintenance work over ceiling cavity areas to avoid the occurrence of similar accidents. In response to the issue of traffic accidents, the plants will conduct regular traffic safety advocacy to enhance personnel’s safety awareness and reduce the incidence of traffic accidents. As for the accidents involving being caught/drawn in by machinery and being crushed/smashed, the occurrence of such accidents shows that further improvement measures are needed for work environment safety and protection. Causes of the accidents have been comprehensively analyzed and examined with reference to similar accidents that happened at peer companies, and improvement measures have been taken in hopes of achieving the goal of zero occupational accidents. The Company has established its accident reporting procedures in accordance with the Regulations on EHS Accident Investigation and Guidelines to Achieve Zero Serious Accidents, which are illustrated in the figure below:

|

|

EMC carries out comprehensive hazard identification every year to determine whether each department’s work items may potentially cause personnel injuries or accidents and further assess existing safety and health protection facilities and review their control effectiveness. By assessing the risk level of each hazard, the Company actively explores the unacceptable risks and sets objectives to improve the occupational safety and health risks. Nevertheless, occupational accidents may still happen due to human, environmental, and management factors. In order to correctly grasp the causes and impacts of EHS accidents, relevant management directions are stipulated for accident investigation, analysis, and subsequent control. The Company keeps complete records of accident occurrences with an aim to prevent recurrences and the loss of Company property and resources. Activities promoting the goal of Zero Major Accidents are also held to encourage employees to actively identify anomalies and report safety concerns and non-conformities, thereby reducing the incidence of occupational accidents

Statistics of employees’ work-related injuries at the Taiwan and Mainland China plants in 2024

|

Summary of Work-related Injury Statistics |

Taiwan Plants |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||||

|

Gender |

Male |

Female |

Male |

Female |

Male |

Female |

Male |

Female |

||

|

Total working hours (hrs) |

1,778,472 |

351,920 |

4,137,703 |

931,220 |

2,213,299 |

555,853 |

1,979,788.5 |

417,562 |

||

|

Disabling Injury Frequency Rate (FR) |

0.56 |

0.00 |

2.175 |

0 |

0.9 |

0 |

2.526 |

0 |

||

|

Total Recordable Incident Rate (TRIR) Note 3 |

5.06 |

8.53 |

2.175 |

2.190 |

1.81 |

0 |

3.031 |

2.395 |

||

|

Total Recordable Incident Frequency Rate (TRIR) Note 4 |

1.01 |

1.71 |

0.483 |

0.215 |

0.36 |

0 |

0.101 |

0.479 |

||

|

Near Miss Frequency Rate (NMFR) Note 5 |

1.13 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

||

|

Near Miss Frequency Rate (NMFR) Note 6 |

0.22 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

||

|

Number of occupational diseases/disorders |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

||

|

Occupational Disease Rate (ODR) |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

||

|

Disabling Injury Severity Rate (SR) |

85.47 |

0.00 |

18.851 |

0 |

2715.4 |

0 |

19.194 |

0 |

||

|

Number of serious occupational accidents |

0 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

||

|

Rate of serious occupational accidents |

0 |

0 |

0 |

0 |

25% |

0% |

0.00% |

0.00% |

||

|

Death toll from work related injuries |

0 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

||

|

Death rate from work related injuries |

0 |

0 |

0 |

0 |

0.09 |

0 |

0 |

0 |

||

Contractors (statistics of Taiwan plants only)

|

Summary of Work-related Injury Statistics |

2024 |

2023 |

||

|

Gender |

Male |

Female |

Male |

Female |

|

Total persons-counts |

5,285 |

4,548 |

||

|

Total working hours (hrs) |

873,768 |

758,300 |

||

|

Disabling Injury Frequency Rate(FR) |

0 |

0 |

0 |

0 |

|

Number of occupational disease/disorder |

0 |

0 |

0 |

0 |

|

Occupational Disease Rate (ODR) |

0% |

0% |

0% |

0% |

|

Disabling Injury Severity Rate (SR) |

0 |

0 |

0 |

0 |

|

Death toll from work-related injuries |

0 |

0 |

0 |

0 |

|

Death rate from work-related injuries |

0% |

0% |

0% |

0% |

1. Disabling Injury Frequency Rate (FR) = (total work-related injury cases / total working hours) ×106

2. Disabling Injury Severity Rate (SR) = (total loss of work days / total working hours) ×106

3. Total Recordable Incident Rate (TRIR) = Number of recordable incidents (including traffic accidents) ÷ Total employee hours worked × 106

4: Total Recordable Incident Rate (TRIR) = Number of recordable incidents (including traffic accidents) ÷ Total employee hours worked × 200,000

5: Near Miss Frequency Rate (NMFR) = Number of reported near misses (number of near accidents) ÷ Total employee hours worked × 106

6: Near Miss Frequency Rate (NMFR) = Number of reported near misses (number of near accidents) ÷ Total employee hours worked × 200,000

7: Occupational Disease Rate (ODR) = Total number of people with occupational diseases × 106 / total working hours

8: Serious Occupational Accidents = Work-related accident that results in a fatality or in an injury from which the worker cannot, does not, or is not expected to recover fully to pre-injury health status within 6 months.

9: Rate of Serious Occupational Accidents = (Number of serious occupational accidents / Total number of work-related injury cases) × 100%

10 Occupational injury-related death rate = (Number of deaths caused by occupational injuries/Total working hours) × 200,000

11 Data included in occupational safety statistics: Disasters where employees suffer work-related injuries or ill health; data do not include approved leave, maternity leave, paternity leave, funeral leave, and general sick leave.

12 EMC conducts employee health checks every year, implements Friendly Work Environment operating environment testing, and actively eliminates potential workplace hazards through Improvement Proposals, Safety Observation, Near Miss Reporting, and other systems. With respect to emergency response procedures, self-inspection, education and training on safety and health, operating environment testing, and other related operations, ongoing reviews, and improvements are carried out every year in the hope of creating a healthy and safe work environment for employees.

|

Plant |

Taiwan Plants |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

Total |

|

Non-employee workers Note |

36 |

70 |

55 |

36 |

197 |

|

Number of employees at the end of the year |

1,103 |

2,116 |

1,173 |

968 |

5360 |

|

Percentage of non-employee workers |

3.26% |

3.2% |

4.69% |

3.72% |

3.68% |

Note:

Non-employee workers refer to workers who are not EMC’s employees, including outsourced personnel, dispatched labor, security guards, cleaners, canteen personnel, etc. The total number of such workers was 197 in 2024, accounting for 3.68% of the total number of employees at EMC’s four plants, and showing no significant fluctuation in comparison with the previous year. When signing contracts with non-employee workers, EMC ensures that their wages and labor conditions comply with the local minimum wage requirements.

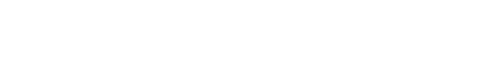

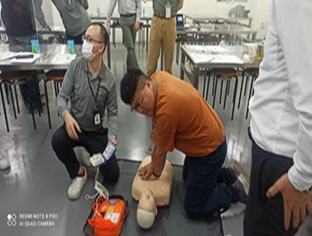

n Education and Training on Occupational Safety and Health

In accordance with the Occupational Safety and Health Education and Training Rules and related regulations, EMC provides new employees with occupational safety and health education and training, which includes general education and training on safety and health and workplace hazards. In addition, training courses are organized in accordance with laws and regulations for the initial training and on-the-job re-training required for supervisors of various operations, which include occupational safety and health management staff, supervisors in charge of hypoxia operations, supervisors in charge of organic solvent operations, operators of forklifts with a capacity of one ton or more, first aid personnel, etc., to maintain the validity of their certificates and reinforce their safety and health awareness. Moreover, other education and training courses on safety and health are conducted on an irregular basis. All education and training courses offered by the Company are conducted during normal work hours. Employees will not suffer punitive treatments such as pay deduction, salary cut, or leave deprivation for their participation in related training.

On-the-job Re-training for EHS Certificate Holders (Targets: Personnel with EHS Certificates)

|

Course Type |

Target |

Taiwan Plants (number of participants) |

Mainland China Plants (number of participants) |

||||

|

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

||

|

Re-training courses for occupational safety certificate holders |

Certificate holders |

68 |

160 |

95 |

587 |

789 |

812 |

|

Re-training courses for fire safety certificate holders |

Certificate holders |

8 |

32 |

36 |

23 |

28 |

32 |

General Safety and Health and Emergency Response Training (Targets: General Employees and Contractors)

In addition to conducting training courses in accordance with the law, EMC also prioritizes the overall safety of employees, contractors, and visitors. In order to actively eliminate potential workplace hazards, each year, the Company organizes whole-plant evacuation drills, fire and chemical accident emergency drills, firefighting training (conducted at the Hsinchu Fire Training Facility), hazard prevention for safe plant operations (i.e., forklift operations, confined space operations, and hot work), and education and training for contractors before entering the plant. By carrying out ongoing reviews and improvements every year, the Company and its employees jointly strive to create a healthy and safe work environment. In 2024, training encompassed 3,109 participants and 32.5 hours of engagement at the Taiwan plants, and 12,822 participants-counts and 135 hours of engagement at the Mainland China plants.

Hazard Awareness for Contractors and Training on Consultative Organization Meetings (Targets: Contractors)

Contractor management is a complicated but essential part of the Company’s business. On the one hand, personnel entering plant areas must be properly controlled; on the other hand, contracted personnel are not plant employees, which raises concerns about whether they have sufficient safety awareness. In addition to holding safety meetings prior to starting construction work, Plant-entry Education and Training and Hazard Awareness Workshops are held by the Safety and Health Department and project organizing units to ensure that contractors fully understand the regulations governing the plant areas. Moreover, project organizing units are required to fill out a Construction Application Form prior to contractors’ plant-entry to confirm the construction date, number of workers, work content, construction location, and other information for the precise management of contractors’ operations.

Contractor assessments have been conducted at the end of each year since 2020 to summarize contractors’ violations during the year, based on which the contractors are classified into Class A, Class B, and Class C. Contractors with more than five violations are classified as Class C, and their contract is suspended for 3 months starting from the assessment date, during which time no further projects are awarded. Since 2023, contractor assessment statistics for the Taiwan plants have been aggregated without separating the Guanyin Plant and the Hsinchu Plant. Results of the 2024 assessment (474 vendors): 469 Class-A vendors, 5 Class-B vendors, and no Class-C vendor.

|

Contractor Assessment Result (Plants in Taiwan) |

||||

|

Contractor Class |

2022 (Guanyin Plant) |

2022 (Hsinchu Plant) |

2023 (Guanyin Plant + Hsinchu Plant) |

2024 (Guanyin Plant + Hsinchu Plant) |

|

Class A |

381 |

335 |

432 |

469 |

|

Class B |

2 |

3 |

5 |

5 |

|

Class C |

0 |

0 |

0 |

0 |

|

Total |

383 |

338 |

437 |

474 |

|

|

|

|

|

|

Emergency evacuation drills (all plant members) |

|

||

|

|

|

|

|

Annual fire and chemical accidents emergency drills (all plant members) |

||

n Prevention and Mitigation of Occupational Safety and Health Impacts

In order to successfully implement the company’s occupational safety and health planning and management, maintain the continuous operation of the management system, and prevent and mitigate business-related occupational safety and health impacts, EMC upholds the principles of its EHS policy and sets annual occupational safety and health goals to create a safe and comfortable work environment for employees. Moreover, improvement goals for the upcoming year are formulated by fully considering the results of hazard identification and risk assessment, internal and external safety and health issues, stakeholders’ demands and expectations, regulatory requirements and other requirements, technical and financial issues, etc.

The Safety and Health Department supervises the heads of all departments and formulates safety and health management plans based on the Company’s EHS policy; details of these plans are recorded on corresponding Goal Planning Charts. Plans that can be completed within the planning year are viewed as short-term plans, whereas plans that take several years (2-3 years) to complete are classified as long-term plans. Since 2012, all departments of EMC have set annual safety and health improvement goals for the following year based on their potential hazards, with the aim of improving the overall safety and health of all plant areas. Several risk control and protective measures were taken for manufacturing sites in 2024, including adding movable aspirators to IQC/IPQC and upgrading the explosion-proof motors in chemical warehouses. These measures will eliminate the risk of accidents during operations and actively promote personnel’s hazard awareness. The Company continued to implement contractors’ plant entry education and training in 2024, which explains the operation precautions for each plant area to construction workers entering the plant areas for the first time, thereby increasing their familiarity with the work environment to improve their safety and health awareness of hazardous operations and helping them comply with laws and regulations. Additionally, safety and health inspections are conducted on an irregular basis to ensure that all operations are carried out in compliance with regulations, aiming to reduce the incidence of contractors’ occupational accidents and create a safe workplace for employees, contractors, customers, and all plant entry personnel.

|

|

|

|

A water mist fire suppression system was installed in the heat transfer oil pump area |

A screw lifting function was added to the packaging platform |

|

|

|

|

|

HFC-227ea (or FM200) Automatic Fire Extinguishing System at Jinmao Plant 1 of Elite Electronic Material (Kunshan) |

Comprehensive upgrades for lifting platform safety protection mechanisms at Elite Electronic Material (Zhongshan) |

Automatic kitchen fire suppression system at Elite Electronic Material (Huangshi) |

n Worker Participation, Consultation, and Communication

EMC has established the Consultation and Communication Management Procedures to help the Company reach an internal consensus on the EHS management system and the Company’s various management mechanisms and establish channels for effective two-way communication with the Company’s internal employees and related external groups regarding the company’s commitment to EHS management and various management mechanisms. Workers should be consulted whenever there are changes in workplace safety and health conditions, and the arrangement of the consultation should be documented, for example, in the form of meeting notices or minutes, and the interested parties should be notified.

Employees are an important asset of EMC; and health and safety are employees’ primary wealth. EMC set up the Occupational Safety and Health Committee to ensure that employees can work in a healthy and safe environment and the company can carry out its safety and health policy. The Committee meets every 3 months and proposes suggestions based on the requirements of the Occupational Safety and Health Act. In 2024, a total of 11 projects were proposed, all of which were accomplished and closed by the end of the year:

|

|

Labor representatives in the Occupational Safety and Health Committee account for 39% of total members (a percentage higher than the statutory standard of one-third). The composition is listed as follows: (1) OS&H Personnel (2) Department heads, supervisors, and leaders (3) OS&H-related engineering and technical personnel (4) Medical personnel engaged in workers’ health services (5) Labor representatives |

11 projects were completed in 2024

|

No. |

ESH Policy |

Goal |

Target |

Action Guideline |

Completion Date |

Improving Unit |

|

1 |

Risk Control |

Increase the flash point of boiler heat transfer oil in Plant 3 |

Increase the flash point of heat transfer oil to reduce fire and explosion risks |

Use CARITHERM-Q7 heat transfer oil, and increase the flash point (193℃→ 261℃ ) to enhance safety when using equipment at high temperatures. |

May 30, 2024 |

Maintenance Department |

|

2 |

Risk Control |

Exhaust equipment improvement in reflow oven area |

Prevent personnel from inhaling hazardous substances |

Connect the oven’s exhaust duct to the main exhaust duct in a sealed manner |

July 31, 2024 |

Production Testing Department |

|

3 |

Risk Control |

Reduce operators’workload |

Lower the height of the unloading shaft to make it the same height as the transport board for operators to exert force with less effort |

Add a screw lifting function to the platform |

July 31, 2024 |

Raw Materials Management Department |

|

4 |

Risk Control |

Reduce the hazards associated with chemical spills |

Minimize operator exposure by reducing the concentration of solvents |

Add anti-spill tray to the lower part of the fume hood |

August 31, 2024 |

Materials Development Department II |

|

5 |

Risk Control |

Reduce static electricity accumulation in glass-fiber workshops |

Avoid fire caused by static electricity |

Increase the use of static ropes to direct and remove static electricity from fabrics |

October 31, 2024 |

Production Department |

|

6 |

Conservation & Waste Reduction |

Reduce waste solvent after glue change |

Minimize the generation of waste solvent and reduce disposal costs |

1. Optimize the cleaning operation when changing glues (the solvents used for the 3rd and 4th cleaning procedures can be used for the 2nd and 3rd procedures of the next cleaning operation) 2. The waste solvent from the 2nd change-glue cleaning procedure is treated through distillation instead of scrapping |

October 31, 2024 |

Production Department |

|

7 |

Legal Compliance |

Improvement of the oil/grease problems in kitchen’s main wastewater discharge pipes |

Kitchen wastewater discharge complies with regulatory discharge standards (COD <560) |

1. Use enzymes to break down grease and prevent it from clumping. 2. Monitor COD values. |

December 31, 2024 |

Human Resources Department |

|

8 |

Legal Compliance |

Comply with environmental regulations. |

Preventive measures and contents of the Cleanup Plan comply with regulatory standards. |

Change or modify the content of the Operating Permit and Cleanup Plan based on the Company’s production status. |

December 31, 2024 |

Department of Safety and Health |

|

9 |

Legal Compliance/ Pollution Prevention |

Reduce air pollution through improved equipment and enhanced prevention capabilities |

Reduce air pollution caused by strong acid volatile gases from acid washing and acid pickling processes |

Upgrade equipment in accordance with current regulations |

April 30, 2024 |

Production Department |

|

10 |

Continuous Improvement |

Comply with waste-related regulations |

Effectively control waste storage locations |

Create gateways for waste substrate and waste copper foil storage areas, and clearly label the control areas. |

June 30, 2024 |

Department of Safety and Health |

|

11 |

Continuous Improvement |

Install fire suppression systems I Zone 3’s OCU area |

Effectively extinguish fire and prevent it from spreading to other areas |

Install a water mist fire suppression system |

December 31, 2024 |

Maintenance Department |

Comprehensive Employee Health Management

EMC is people-oriented and always attaches great importance to the health and safety of personnel. With respect to employee health management, in addition to providing free health checks and graded health management in accordance with laws and regulations, the Company also stations nurses in plant areas and arranges for occupational health specialists to provide monthly onsite services for employees, including work-related health consultations, medical guidance, improvement suggestions, and followup attention to confirm improvement status after health checks. Maternal health protection programs are promoted for female employees to protect the health of pregnant and postnatal employees, which include the provision of a breastfeeding room, relevant health guidance, health education, consultation, and assessments of hazardous operational risks, health status, and fitness-for-work.

EMC conducts required employee health checks and special health checks in accordance with the frequencies stipulated in the Occupational Safety and Health Act. In 2024, a total of 195 employees were required to take general health checks, 183 of whom participated in the checks, achieving a coverage rate of 93%. A total of 188 employees were required to take special health checks in 2024; among them, 188 participated in the checks, achieving a coverage rate of 100%.

|

|

|

|

|

|

|

|

|

|

|

In-plant health promotion activities |

|||

Occupational health specialists are invited to the plants every month to provide on-site services related to employees’ health check results, including relevant health consultations, medical guidance, improvement suggestions, and follow-up attention to confirm improvement status after health checks. Through the combination of on-site services provided by occupational health specialists, progress tracking, and relevant management measures, employees’ health has improved considerably.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Employment Status

n Human Resources Structure

As a corporate citizen of the global community, EMC explicitly prohibits the use of child labor and ensures that no laborers under the legal working age are employed. The physical and psychological health and safety of underage employees are protected, and they cannot be assigned to dangerous work. In Taiwan plants and Mainland China plants, the managerial positions (positions at or above the manager level) are all served by locals.

As of the end of 2024, EMC’s had a total of 5,310 employees. A year-by-year rise in employee numbers has been observed along with EMC’s increased production momentum following the COVID-19 pandemic. At both the Taiwan plants and the Mainland China plants, the majority of employees are under the age of 50, accounting for more than 85% of EMC’s overall workforce on average. The male to female sex ratio in the Company’s workforce is relatively high due to the industry’s characteristics, job market conditions, and other related factors. Despite this, the percentage of female managerial personnel is still maintained at 10% or above. Additionally, to achieve employee diversity, the percentage of employees with disabilities is also increasing year by year.

|

|

|

2024 Labor Composition at Taiwan and Mainland China Plants (statistics as of December 31, 2024)

|

|

|

n New Employee Hires and Employee Turnover

In terms of employee recruitment, all candidates are treated equally regardless of gender, religion, political affiliation, marital status, etc. Employees should be provided with a good work environment that is free from discrimination and harassment. The company also promotes freedom of employment, meaning that all work is taken on voluntarily. An Employee Complaint Management System has been established to deal with employee grievances. Moreover, an Employee Mailbox has been set up to collect employees’ suggestions, further expanding the communication channels. The Company’s turnover statistics also include foreign employees who returned to their home countries after their contracts expired, as well as officially employed personnel who retired at the age of 65 as per the Labor Standards Act or voluntarily retired early in accordance with the law. If a labor contract is terminated by the employer or the employee for any reason, the Company will give advance notice in accordance with relevant laws and within the specified period.

At the Taiwan plants, the new employee hiring rate increased by 10.72% in 2024 compared to 2023, indicating an increase in manpower demand driven by the expansion of business and production capacity. The turnover rate increased by 2.08% in 2024 compared to the previous year, which is mainly attributed to factors such as increased labor turnover in the overall market, specific departments’ organizational adjustments, and employees’ career

planning.

At the Mainland China plants, many employees were recruited in response to production capacity expansion, leading to a significant rise in the new employee hiring rate. With competitive salary offerings in the same industry and geographic area, excellent business operations, and the Company’s emphasis on stable employment and income for entry-level employees, combined with the downturn in the external environment, EMC achieved a significant turnover decrease in 2024.

|

|

|