Environmental Management Systems

Environmental Policy:

In addition to monitoring global environmental issues and trends, EMC has introduced the ISO 14001 Environmental Management Systems at all of its plants to ensure compliance with local governments’ environmental regulations, enhance business performance, effectively reduce the impact of business activities on the environment, improve environmental management, and move forward toward sustainable development. EMC is committed to strictly complying with environmental and energy regulations related to its business activities, products and services, and the Company has pledged to meet customers’ needs by gradually achieving set targets or performing beyond the usual standards. Moreover, EMC will conduct regular regulatory compliance checks to ensure that its current practices comply with the latest regulations, and the Company will carry out yearly internal audits and external third-party verification to ensure the effective operations of all environment management systems.

【EMC Plants' ISO 14001 Environmental Management Systems Certificates】

|

|

|

|

|

|

Taiwan Plants |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

Energy Use and Management

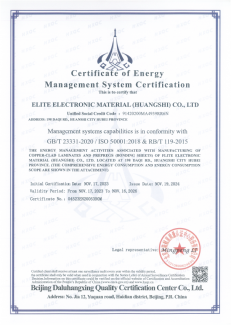

EMC’s energy consumption is derived mainly from electricity, followed by natural gas and small amounts of petrol/diesel as well as liquefied petroleum gas (including propane). Therefore, EMC’s energy management guidelines prioritize improving energy efficiency and increasing the percentage of renewable energy use. With the aim of achieving systematic energy management, EMC has introduced the ISO 50001 Energy Management Systems. Through the effective operation of the systems combined with real-time energy data dashboards, the Company identifies energy consumption hotspots and conducts relevant analysis to develop effective energy projects for energy saving. EMC’s overall energy efficiency is improving as a result of its efforts in holding regular carbon reduction or energy project meetings, which track projects’ implementation progress and results and encourage experience sharing among plants to enhance relevant practices. EMC’s Mainland China plants have all obtained the ISO 50001 certification, and the Taiwan plants will officially introduce the systems in 2025.

【EMC Plants’ ISO 50001 Energy Management Systems Certificates】

|

|

|

|

|

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

EMC implements control and management measures over each plant’s manufacturing processes and communal machines/facilities as well as the general electrical devices used by the Company. Staff are required to save electricity, water, oil, and fuel and avoid wasting resources. With the aim of raising awareness of energy and resource conservation and appreciation among EMC members, the Company’s Maintenance Department regularly compiles energy statistics and monitors the Company’s energy consumption status to facilitate improvement measures and effectively implement energy conservation.

On the basis of EMC’s energy consumption data over the past 3 years, the total energy consumption in 2023 (including electricity, natural gas, etc.) was higher than that in 2022 due to the increase in overall production capacity and volume in 2023. The purchased electricity consumption intensity per unit of sales revenue (per NT$ million of revenue) in 2023 decreased by only 0.44% compared to 2022, and the energy consumption intensity per unit of sales revenue decreased by 3.67% compared to 2022.

To further reduce the purchased electricity consumption intensity per unit of sales revenue and the energy consumption intensity per unit of sales revenue, EMC focused its efforts on enhancing revenue/production value and improving energy efficiency in 2024. Even though the Company’s production capacity, production volume, and total energy consumption all increased in 2024 relative to previous years, and this was coupled with an increase in purchased electricity and natural gas consumption, EMC’s purchased electricity consumption intensity per unit of sales revenue decreased by 24.62% compared with 2023, and its energy consumption intensity per unit of sales revenue decreased by 22.97% (a decrease of 25.80% compared to 2022), demonstrating EMC’s significant progress in enhancing energy efficiency and reducing energy consumption per unit of sales revenue!

【EMC's Energy Consumption Data from the Past 3 Years】

Plant |

Taiwan Plants |

Mainland China Plants |

USA Plant |

Total |

||||||||||||

|

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

|||||

|

Energy Consumption 【Unit of measurement according to prototype】 |

||||||||||||||||

|

Purchased Electricity [Power] |

(MWh /year) |

47,685.90 |

40,655.00 |

42,191.60 |

127,523.27 |

145,179.87 |

176,920.21 |

3,450.57 |

4,115.47 |

4,108.83 |

178,659.74 |

189,950.34 |

223,220.64 |

|||

|

Natural Gas |

(thousand cubic meters/year) |

4,517.10 |

4,840.05 |

4,934.54 |

15,861.29 |

17,483.84 |

22,325.11 |

215.16 |

222.53 |

217.61 |

20,593.55 |

22,546.42 |

27,477.27 |

|||

|

Heavy Oil--used for the boiler steam process |

(kL/year) |

1,830.00 |

- |

- |

- |

- |

- |

- |

- |

- |

1,830.00 |

- |

- |

|||

|

Petrol |

(liter/year) |

358.01 |

346.97 |

943.56 |

50,037.60 |

66,269.17 |

82,482.99 |

- |

- |

- |

50,395.61 |

66,616.14 |

83,426.55 |

|||

|

Diesel |

(liter/year) |

12,152.92 |

8,400.29 |

11,953.05 |

64,340.09 |

49,052.55 |

98,096.39 |

- |

- |

- |

76,493.01 |

57,452.84 |

110,049.44 |

|||

|

Liquefied Petroleum Gases [LPG] |

(liter/year) |

16,341.90 |

19,361.70 |

19,907.10 |

- |

- |

- |

359.31 |

378.34 |

305.67 |

16,701.21 |

19,740.04 |

20,212.77 |

|||

|

Renewable Energy 【GEC not included]】 |

(MWh /year) |

- |

- |

- |

- |

620.81 |

990.81 |

- |

- |

- |

- |

620.81 |

990.81 |

|||

|

Energy Consumption【Converted to GJ/year】 |

||||||||||||||||

|

Purchased Electricity [Power] |

(GJ/year) |

171,669.24 |

146,358.00 |

151,889.76 |

459,083.78 |

522,647.53 |

636,912.75 |

12,422.05 |

14,815.68 |

14,791.80 |

643,175.07 |

683,821.21 |

803,594.30 |

|||

|

Natural Gas |

(GJ/year) |

170,177.15 |

182,343.98 |

185,903.89 |

597,558.30 |

658,686.05 |

841,076.34 |

8,105.92 |

8,383.61 |

8,198.34 |

775,841.38 |

849,413.64 |

1,035,178.57 |

|||

|

Heavy Oil--used for the boiler steam process |

(GJ/year) |

73,539.65 |

- |

- |

- |

- |

- |

- |

- |

- |

73,539.65 |

- |

- |

|||

|

Petrol |

(GJ/year) |

11.69 |

11.33 |

30.81 |

1,633.77 |

2,163.74 |

2,693.14 |

- |

- |

- |

1,645.46 |

2,175.07 |

2,723.94 |

|||

|

Diesel |

(GJ/year) |

427.33 |

295.37 |

420.30 |

2,262.35 |

1,724.81 |

3,449.30 |

- |

- |

- |

2,689.68 |

2,020.18 |

3,869.60 |

|||

|

Liquefied Petroleum Gases [LPG] |

(GJ/year) |

453.88 |

537.75 |

552.90 |

- |

- |

- |

9.98 |

10.51 |

8.49 |

463.86 |

548.26 |

561.39 |

|||

|

Renewable Energy 【GEC not included]】 |

(GJ/year) |

- |

- |

- |

- |

2,234.89 |

3,566.87 |

- |

- |

- |

- |

2,234.89 |

3,566.87 |

|||

|

Total Energy Consumption |

(GJ/year) |

416,278.94 |

329,546.44 |

338,797.66 |

1,060,538.20 |

1,187,457.02 |

1,487,698.39 |

20,537.96 |

23,209.79 |

22,998.63 |

1,497,355.10 |

1,540,213.26 |

1,849,494.68 |

|||

|

Consolidated revenue (Unit: NT$ million) |

38,672.549 |

41,296.217 |

64,376.727 |

|||||||||||||

|

Purchased electricity consumption intensity per unit of sales revenue【Total purchased electricity ( MWh /year)/Consolidated revenue (NT$ million)】 |

4.62 |

4.60 |

3.47 |

|||||||||||||

|

Changes in purchased electricity consumption intensity per unit of sales revenue (Compared with previous year/YoY) |

--- |

⬇ -0.44% |

⬇ -24.62% |

|||||||||||||

|

Energy consumption intensity per unit of sales revenue【Total energy consumption (GJ/year)/Consolidated revenue (NT$ million)】 |

38.72 |

37.30 |

28.73 |

|||||||||||||

|

Changes in energy consumption intensity per NT$ million of revenue (Compared with previous year/YoY) |

--- |

⬇ -3.67% |

⬇ -22.97% |

|||||||||||||

Note:

1. Due to coefficient unit typographical errors that occurred in 2022 and 2023 when converting the various energy units into joules, the data indicated in 2022 and 2023 sustainability reports required correction. The corrected data is shown in the table above.

2. The heating values shown in the table were calculated by referencing the Table of Energy Product Unit Heating Values contained in the Energy Statistics Handbook (updated on October 4, 2024) issued by the Energy Administration, MOEA. Heating value conversion factor: 1 Kcal = 4,186 J;1 GJ=109 J

3. The scope of the above energy statistics includes EMC’s plants in Taiwan: Guanyin Plant and Hsinchu Plant; EMC’s Mainland China plants: Elite Electronic Material (Kunshan), Elite Electronic Material (Zhongshan), and Elite Electronic Material (Huangshi); and EMC’s USA plant: Arlon EMD.

Currently, EMC’s plants in Taiwan only use purchased energy, including purchased electricity and natural gas. No carbon offsets or renewable energy certificates (T-REC: Taiwan Renewable Energy Certificate) have been adopted. As for the Mainland China plants, Kunshan Plant and Zhongshan Plant installed solar (photovoltaic) panels in 2023 to generate power for self-consumption and facilitate the use of renewable energy. In additional, Huangshi Plant purchased its first Green Energy Certificates (GECs) in 2024. To sum up, in 2024, EMC’s Mainland China plants achieved 990MWh of solar power generation for self-consumption, and obtained 600 green energy certificates (600MWh of electricity). Therefore, the Mainland China plants’overall renewable energy usage percentage in 2023 was 0.43%, and the percentage in 2024 was 0.90%, showing a significant increase in renewable energy usage.

【EMC's Purchased Electricity & Renewable Energy Consumption Data of the Past 3 Years】

|

Plant |

Taiwan Plants |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

||||||||||||||

|

Year |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

||||||

|

Renewable Energy 【including energy generated for self consumption and renewable energy certificates】 |

(MWh)) |

- |

- |

- |

- |

494.478 |

474.100 |

- |

126.332 |

516.708 |

- |

- |

600.000 |

|||||

|

Percentage of Purchased Electricity |

(%) |

100% |

100% |

100% |

100% |

99.17% |

99.38% |

100% |

99.71% |

98.90% |

100% |

100% |

98.90% |

|||||

|

Renewable Energy (Green Energy) Usage Rate【including energy generated for self consumption and renewable energy certificates】 |

|

- |

- |

- |

- |

0.83% |

0.62% |

- |

0.29% |

1.10% |

- |

- |

1.10% |

|||||

|

|

||||||||||||||||||

|

Renewable energy (green energy) consumption in Mainland China plants |

Year |

2023 |

2024 |

|||||||||||||||

|

Mainland China plants’purchased electricity (MWh) |

145,179.87 |

176,920.21 |

||||||||||||||||

|

Mainland China plants’ renewable energy (green energy)usage rate 【including energy generated for self-consumption and renewable energy certificates】 |

0.43% |

0.90% |

||||||||||||||||

After setting its carbon reduction targets in early 2025, EMC further established targets related to green energy (renewable energy) usage. The medium/long-term target is “Taking 2023 as the base year, EMC aims to achieve a 25% carbon reduction by 2030 through the adoption of green energy, and achieve 100% renewable energy use by 2050 as required by government and international standards”. The short-term target is “Taking 2023 as the base year, the carbon reduction percentage achieved through EMC’s use of green energy will exceed 0.5% by 2025”. To achieve these targets, the Taiwan plants are scheduled to obtain their initial renewable energy certificates (RECs) in 2025, and Mainland China plants will further increase their proportion of green energy and Green Energy Certificate (GEC) usage.

Greenhouse Gas Inventory

EMC follows ISO 14064-1: 2018 standards and consults the GHG Protocol to conduct its GHG emissions inventory. The inventory process and results help the Company understand each plant’s GHG emission volumes and emission status so that feasible solutions can be developed to reduce GHG emissions. To enhance the credibility of GHG inventory information and the inventory report, and to improve the quality of the GHG inventory, after internal verification is completed, an impartial third-party verification agency is appointed (British Standards Institution [BSI] for the Taiwan plants and Mainland China plants, and Sustainability Assurance Services [SAS] for the Arlon EMD plant in the USA) to conduct external verification to ensure the completeness of inventory processes, improve data quality, and establish a complete GHG inventory database.

EMC adopts the operational control method to calculate its GHG emissions. The GWP values stated in the IPCC Sixth Assessment Report (2021) were used for the calculation. To effectively control the environmental impacts of GHG emissions, EMC uses GHG emissions intensity (Category 1 + Category 2 GHG emissions [tCO2e]/Total consolidated revenue [NT$ million]) as a metric for greenhouse gas management. The reduction in GHG emissions intensity has been disclosed annually since 2022. This year’s report newly includes GHG inventory information for the Arlon EMD plant in the USA from the past 3 years.

In 2023, due to the site expansion of Elite Electronic Material (Kunshan) and increased production in various plants, EMC's overall GHG emissions increased significantly, and the overall GHG emissions intensity increased by 3.19% compared to 2022. To effectively resolve the issue of increased emissions intensity caused by increased production, EMC promoted several energy-saving measures in 2024 to improve day-to-day operational efficiency and carried out facility maintenance and improvement in areas of the plants with higher energy consumption. Due to these efforts, in 2024, despite an increase in overall category 1 and category 2 emissions due to increased production, the category 1 + category 2 GHG emissions intensity (total category 1 + category 2 GHG emissions [tCO2e]/Total consolidated revenue [NT$ million]) decreased significantly by 29.87% compared to 2023. This demonstrated EMC’s constant commitment to energy saving and carbon reduction, as the Company decreased GHG intensity while still pursuing production and revenue growth.

【EMC’s Scope 1 and 2 GHG Inventory Statistics of the Past 3 Years】

|

Plant |

Taiwan Plants |

Mainland China Plants |

USA Plants |

Total |

|||||||||||

|

Year |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

|||

|

Category 1 (Scope 1) |

(tCO2e/year) |

15,266.850 |

15,637.2609 |

14,276.3497 |

44,225.75 |

54,765.56 |

59,855.21 |

3,308 |

3,327 |

3,320 |

62,800.600 |

73,729.8209 |

77,451.5597 |

||

|

CO2 |

14,634.375 |

14,987.6605 |

13,596.7518 |

38,148.38 |

51,643.85 |

55,843.84 |

3,308 |

3,327 |

3,320 |

56,090.685 |

69,958.4405 |

72,760.5218 |

|||

|

CH4 |

110.980 |

124.2611 |

101.3776 |

271.29 |

283.45 |

340.05 |

0.06 |

0.06 |

0.06 |

382.330 |

407.7711 |

441.4876 |

|||

|

N2O |

16.626 |

4.8867 |

5.0232 |

27.44 |

29.94 |

42.93 |

0.01 |

0.01 |

0.01 |

44.076 |

34.8367 |

47.9632 |

|||

|

HFCs |

504.869 |

520.4526 |

573.1971 |

5,778.64 |

2,808.32 |

3,628.39 |

0.00 |

0.00 |

0.00 |

6,283.509 |

3,328.7726 |

4,201.5871 |

|||

|

PFCs |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|||

|

SF6 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|||

|

NF3 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|||

|

Category 2 (Scope 2) |

(tCO2e/year) |

24,272.123 |

20,083.5700 |

20,842.6504 |

73,213.84 |

82,796.08 |

94,935.38 |

780 |

874 |

817 |

98,265.963 |

103,753.6500 |

116,595.0304 |

||

|

Total of Category 1 and Category 2 (Total of Scope 1 and Scope 2) |

(tCO2e/year) |

39,538.973 |

35,720.8309 |

35,119.0001 |

117,439.59 |

137,561.64 |

154,790.59 |

4,088 |

4,201 |

4,137 |

161,066.563 |

177,483.4709 |

194,046.5901 |

||

|

Total Consolidated revenue (NT$ million) |

38,672.549 |

41,296.217 |

64,376.727 |

||||||||||||

|

Category 1 + Category 2 GHG emissions intensity 【Total Category 1 + Category 2 GHG emissions (tCO2 e) / Total Consolidated revenue (NT$ million)】 |

4.1649 |

4.2978 |

3.0142 |

||||||||||||

|

Changes in GHG emissions intensity (per NT$ million of revenue) (Compared with previous year/YoY) |

|

⬆ 3.19% |

⬇ - 29.87% |

||||||||||||

Note:

1. The above Category 1 and Category 2 inventory scope includes EMC’s plants in Taiwan: Guanyin Plant and Hsinchu Plant; Mainland China plants: Elite Electronic Material (Kunshan), Elite Electronic Material (Zhongshan), and Elite Electronic Material (Huangshi); and USA plant: Arlon EMD. Location-based factors are used for Category 2 emissions calculation.

2. Different assurance agencies may adopt different rules for presenting decimal numbers and rounding values to different decimal places when disclosing GHG inventory data. The values presented in the table above are consistent with those indicated in the assurance statements issued in the corresponding years

【EMC’s Carbon Emissions and Intensity per NT$ Million Revenue: 3-Year Overview】

【EMC’s Scope 3 GHG Inventory Statistics for the Past 3 Years (partial)】

|

Plant |

Taiwan Plants |

Mainland China Plants |

Total |

|||||||||

|

Year |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

|||

|

Category 3: Indirect Greenhouse Gas Emissions from Upstream Transportation |

(tCO2e/year) |

1,131.836 |

1,409.6179 |

2,762.0093 |

4,585.80 |

10,044.05 |

10,787.66 |

5,717.636 |

11,453.6679 |

13,549.6693 |

||

|

3-1 Upstream raw material transportation and distribution (4) |

279.7255 |

432.1321 |

1,716.8087 |

2,600.10 |

4,069.84 |

8,015.70 |

2,879.825 |

4,501.9721 |

9,732.5087 |

|||

|

3-2 Business trips(6) |

121.7997 |

331.4272 |

298.4972 |

13.90 |

369.30 |

560.69 |

135.700 |

700.7272 |

859.1872 |

|||

|

3-3Employees’commuting (7) |

730.3107 |

646.0586 |

746.7034 |

280.50 |

569.34 |

386.49 |

1,010.811 |

1,215.3986 |

1,133.1934 |

|||

|

3-4Downstream transportation and distribution (9) |

- |

- |

- |

1,691.30 |

5,035.57 |

1,824.78 |

1,691.300 |

5,035.5700 |

1,824.7800 |

|||

|

Category 4: Indirect Greenhouse Gas Emissions from Products Used by the Organization |

(tCO2e/year) |

7,084.895 |

7,084.2562 |

7,273.6074 |

182,172.59 |

292,705.88 |

493,456.73 |

189,257.485 |

299,790.1362 |

500,730.3374 |

||

|

4-1Procurement of goods and services (1) |

- |

- |

6,683.9017 |

139,126.70 |

292,066.26 |

460,597.2400 |

139,126.7000 |

292,066.2600 |

467,281.1417 |

|||

|

4-2Capital goods (2) |

- |

- |

- |

32,299.80 |

- |

- |

32,299.8000 |

- |

- |

|||

|

4-3Fuel- and energy-related activities (3) |

6,705.6734 |

6,479.0182 |

- |

8,483.25 |

238.40 |

29,386.7900 |

15,188.9234 |

6,717.4182 |

29,386.7900 |

|||

|

4-4Waste generated in operations (5) |

379.2211 |

605.2380 |

589.7057 |

2,262.84 |

401.22 |

3,412.4000 |

2,642.0611 |

1,006.4580 |

4,002.1057 |

|||

|

4-5Leased out employee dormitories/Offices/Warehouses |

- |

- |

- |

- |

- |

60.3000 |

- |

- |

60.3000 |

|||

|

Total of Category 3 & Category 4 |

(tCO2e/year) |

8,216.731 |

8,493.874 |

10,035.617 |

186,758.390 |

302,749.930 |

504,244.390 |

194,975.121 |

311,243.8041 |

514,280.0067 |

||

Note:

1. The numbers in parentheses after Category 3 and Category 4 sub-items represent the codes for identification/quantification/classification defined based on the GHG Protocol Scope 3 Evaluator Tool

2. The above category 3 and category 4 inventory scope includes EMC’s Taiwan plants: Guanyin Plant and Hsinchu Plant; and Mainland China plants: Elite Electronic Material (Kunshan), Elite Electronic Material (Zhongshan), and Elite Electronic Material (Huangshi).

3. According to ISO 14064:2018, for Category 3 to Category 6 emissions, an organization can use the Other Indirect Greenhouse Gas Emissions Sources Identification Questionnaire to assess inventory feasibility based on different considerations, and then select the applicable and appropriate emission source options for the organization. Therefore, EMC’s plants selected the applicable subitems and other indirect GHG emission sources under Category 3 and Category 4 for the GHG inventory based on their organizational scope, operating activities, and product characteristics. Since Category 5: Indirect GHG emissions from the Use of the Organization’s Products and Category 6: Other Sources are not applicable, they are not included in the inventory. In other words, the statistics and totals in the table above are not equivalent to the complete information of EMC’s Scope 3 or Categories 3 to 6 inventory results.

Carbon Reduction Goals, Actions, and Achievements

Climate change is a challenge requiring the combined efforts of the entire world. EMC strives to cope with this issue while seeking continuous increases in production. In consideration of factors such as continuously growing production capacity, reasonable carbon reduction planning, trends in the PCB industry, and both regional and international regulations, the Company has set 2023 as the base year for carbon inventory, and aims to achieve a 30% carbon reduction by 2030, then achieve net zero carbon emissions by 2050 as required by government and international standards. Meanwhile, as suggested in the aforementioned carbon reduction targets, by taking 2023 as the base year, the Company aims to achieve a 25% carbon reduction through the adoption of green energy by 2030. Based on the Company’s estimates the percentage of green energy usage will be approximately 47% by then. As the Company’s plant expansion and capacity improvement plans are currently in the implementation stage, the scope of the set carbon reduction targets does not include new production lines and plants in the USA and Malaysia.

【EMC’s Plan for 2030 Carbon Reduction Targets and Carbon Reduction Pathways】

Note:

1. The Company’s production is currently increasing; therefore, absolute carbon emissions will also increase accordingly. Until carbon emissions reach their peak, to ensure solid carbon

reduction achievements, the Company’s carbon emissions intensity metrics (such as the carbon emissions intensity per NT$ million of revenue) should decrease year by year.

2. At the current stage, the set carbon reduction targets do not yet include newly established production lines, new plants, or the facilities in the USA and Malaysia.

Carbon Reduction Actions and Achievements:

EMC is committed to actively addressing. Regarding EMC’s existing carbon reduction plans, departments of the plants shall cooperate with maintenance units in carrying out facility maintenance and improvements for energy-consuming areas within the plants based on annual GHG inventory results. Moreover, all plants must pay constant attention to the impact of their production and operation activities on climate change. To cooperate with the Company’s energy saving, carbon reduction, and GHG reduction strategies and goals, the plants compiled statistics on the benefits brought by various improvement projects for energy conservation and carbon reduction in 2024. One of the improvement projects was to replace the heavy oil used in the plants’ air pollution control facilities with natural gas that produces lower carbon emissions. Another example was to upgrade the motors of the water pumps used for air conditioning facilities to energy-efficient ones based on the recommendations of the ITRI energy saving team. By adding temperature controllers to the water pumps, the Company reduced power consumption, enhanced energy efficiency, and achieved carbon reduction effects. Through the implementation of carbon reduction projects, plants in Taiwan and Mainland China reduced their carbon emissions by 1,620 tCO2e in 2024..

Climate change has become a global challenge that requires collective action, and EMC is committed to actively addressing this issue. As part of its ongoing carbon reduction initiatives, departments at each plant work collaboratively with maintenance units to conduct equipment maintenance and improvements in high energy-consuming areas based on the results of the annual greenhouse gas (GHG) inventory.

【2024 Energy-saving Measures, Practices, and Achievements】

|

Plant |

Taiwan Plants |

Elite Electronic Material (Kunshan) |

Elite Electronic Material (Zhongshan) |

Elite Electronic Material (Huangshi) |

|

Energy saving Measures |

1. Installed variable frequency drives (VFDs) to control the chilled water temperature difference, allowing chiller pump motors to operate between 40–60 Hz 2. Improved cooling system water quality by adopting soft water in the cooling water system to reduce scale formation and maintain heat exchange efficiency 3. Replaced cooling tower’s general fan blades with thick, wing-shaped, energy saving fan blades that consume less electricity for the same air volume 4. Replaced outdated IE1 and IE2 motors with IE3 motors to improve motor efficiency 5. Reduced the operation time of the wastewater equalization tank’s 15 kW air blower (Before: 24 HR operation; After: 16 HR when in use) 6. Installed variable frequency drives to Plant 1’s three compressor zone pumps 7. Installed variable frequency drives to Plant 2’s three compressor zone pumps |

1. Jinmao Plant 1’s solar street lights: Replaced aging street lights with hybrid solar/grid-powered street lights, tripling illumination while reducing power consumption of each light from 100 W to 60 W (33 lights) 2. Jinmao Plant 1: Upgraded phase II gluing machine fan motors to level-2 explosionproof energy-efficient motors 3. Jinmao Plant 2: Implemented energy efficiency optimization for compressor supporting systems 4. Jinmao Plant 2: Implemented energy efficiency optimization for gluing machine process cooling water system 5. Upgraded the air handling unit fan in Jinmao Plant 1’s gluing machine 1#/2# air to an EC fan 6. Jinmao Plant 2: Energy-efficiency optimization for air compressor systems 7. Youbi Plant: Low nitrogen transformation in boilers (Adding hot air recovery function to reduce natural gas consumption) |

1. Converted the heat transfer oil pump control from fixed-frequency variable frequency control 2. Changed the liquid ring vacuum pump to a permanent magnet variable frequency (PMVF) screw vacuum pump 3. Changed the fixed frequency control of the phase III RTO combustion-supporting fan to variable frequency control 4. Reduced gluing machine process air volume 5. Improved the substrate cutting machine air cabinet 6. Upgraded the energy efficiency level of the Material Management Department’s three phase manual warehouse air conditioner from Level 3 to Level 2 |

1. Changed PRA/C combination air conditioner to EC fan Changed air handling unit’s general fan to EC energy-saving fan 2. Changed glue-mixing tank’s explosionproof industrial light to an energy-saving explosion-proof industrial light, and changed the original 200 W explosion-proof industrial light to a 100 W energy-saving explosion-proof industrial light 3. Used energy-saving LED tubes for workshop onsite lighting (1) Replaced ordinary 16 W lighting tubes with 8 W energy-saving tubes (2) Used energy-saving LED tubes for Office Building 2F and Plant 1’s visitor corridor lighting (3) Replaced ordinary 8 W light tubes with 4W super energy-saving light tubes |

|

Reduced Energy Consumption |

Total reduced electricity consumption: 753,720kWh/year |

Total reduced electricity consumption: 973,054 kWh/year Reduced natural gas consumption: 171,510 NM3/year |

Total reduced electricity consumption: 355,560 kWh/year |

Total reduced electricity consumption: 137,056 kWh/year |

|

Carbon Reduction Achievement |

372.338tCO2e/year |

Carbon reduction from electricity saving: 676.2725tCO2e/year Carbon reduction from natural gas saving: 370.4616tCO2e/year Total carbon reduction: 1,046.7341tCO2e/year |

158.2242tCO2e/year |

43.1726tCO2e /year |

|

Total |

About 1,620tCO2e |

|||

Note:

1. Taiwan plants adopted the electricity emission factor announced by Taipower in 2023: 0.494 tCO2e/ MWh.

2. Mainland China plants:

■ Elite Electronic Material (Kunshan): Study on CO2 Emission Factors of China's Regional (Jiangsu) Power Grid (2023), 0.695 kg CO2e/kWh.

■ Elite Electronic Material (Zhongshan): Study on CO2 Emission Factors of China's Regional (Guangdong) Power Grid (2023), 0.445 kgCO2e/kWh.

■ Elite Electronic Material (Huangshi): Study on CO2 Emission Factors of China's Regional (Hubei) Power Grid (2023), 0.315 kgCO2e/kWh.

3. If the 2022 National Average CO2 Emission Factor for Electricity: 0.5366 kgCO2/kWh were adopted for all plants in Mainland China, the total carbon reduction achievement by EMC plants (Taiwan and Mainland China) would be 1,529.278 tCO2e.